Skateboarding is a popular sport and recreational activity that has gained immense popularity over the years. It involves riding on a specially designed board with wheels, performing tricks and stunts while balancing on the board. Skateboards are made up of various materials including wood, metal, plastic, and composite materials. However, the most common material used in making skateboards is wood. But have you ever wondered how many pieces of wood are used in making a skateboard? In this article, we will delve into the details of how a skateboard is made and how many pieces of wood are involved in the process.

The Anatomy of a Skateboard

Before we dive into the number of wood pieces used in making a skateboard, let’s first understand the different components that make up a skateboard. A typical skateboard consists of the following parts:

- Deck: The main part of a skateboard, also known as the board or platform, is called the deck. It is usually made of multiple layers of wood veneers pressed together with glue.

- Trucks: These are metal T-shaped structures mounted underneath the deck that hold the wheels and allow the skateboard to turn.

- Wheels: Skateboard wheels are usually made of polyurethane and come in different sizes and hardness levels.

- Bearings: These small metal balls fit inside the wheel’s hub and help reduce friction, allowing for a smooth ride.

- Grip tape: This is a sheet of sandpaper-like material applied on top of the deck to provide grip and prevent the rider’s feet from slipping.

Now that we have a better understanding of the different parts of a skateboard, let’s move on to how they are put together.

The Making of a Skateboard Deck

When it comes to making a skateboard, the process is quite fascinating, especially for the deck. The deck is essentially the backbone of the skateboard on which the rider stands, and it’s typically made from several thin sheets of wood, known as veneers. These veneers are generally made from hard rock maple due to its sturdy and flexible nature, perfect for withstanding the intense rigors of skateboarding.

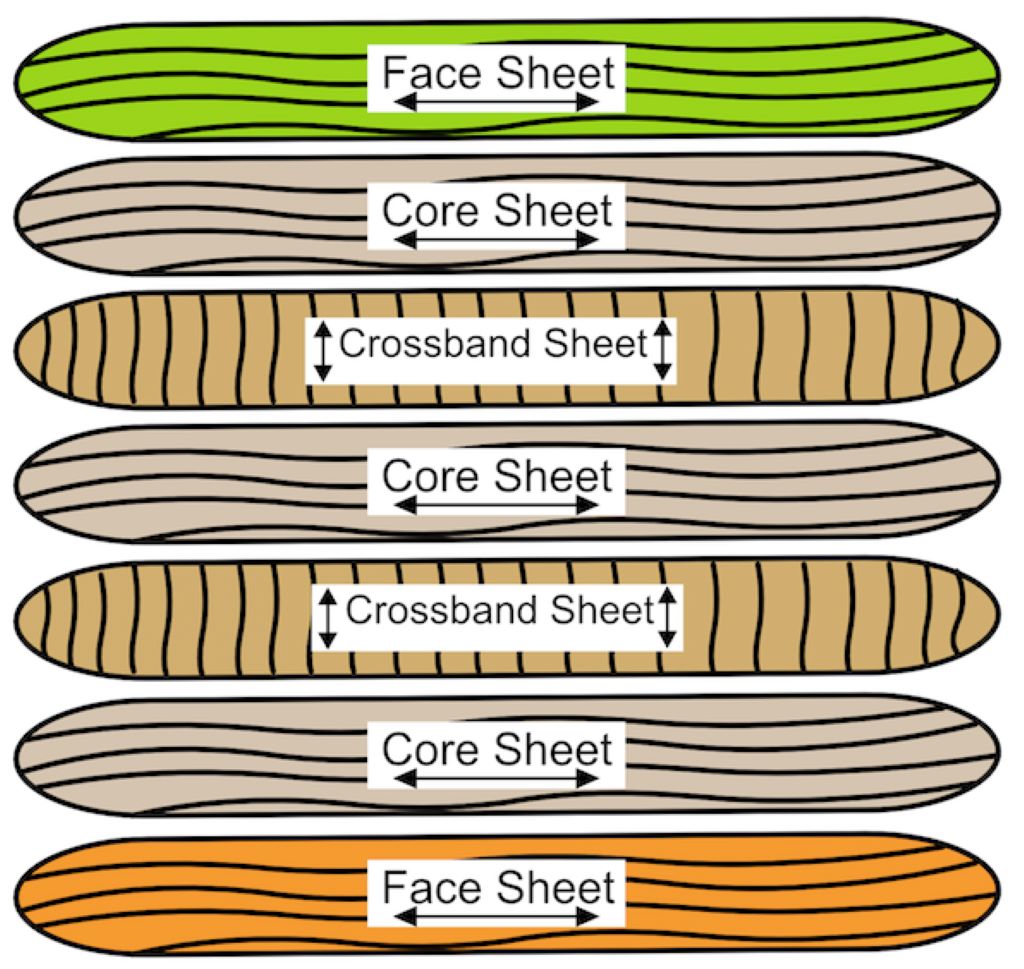

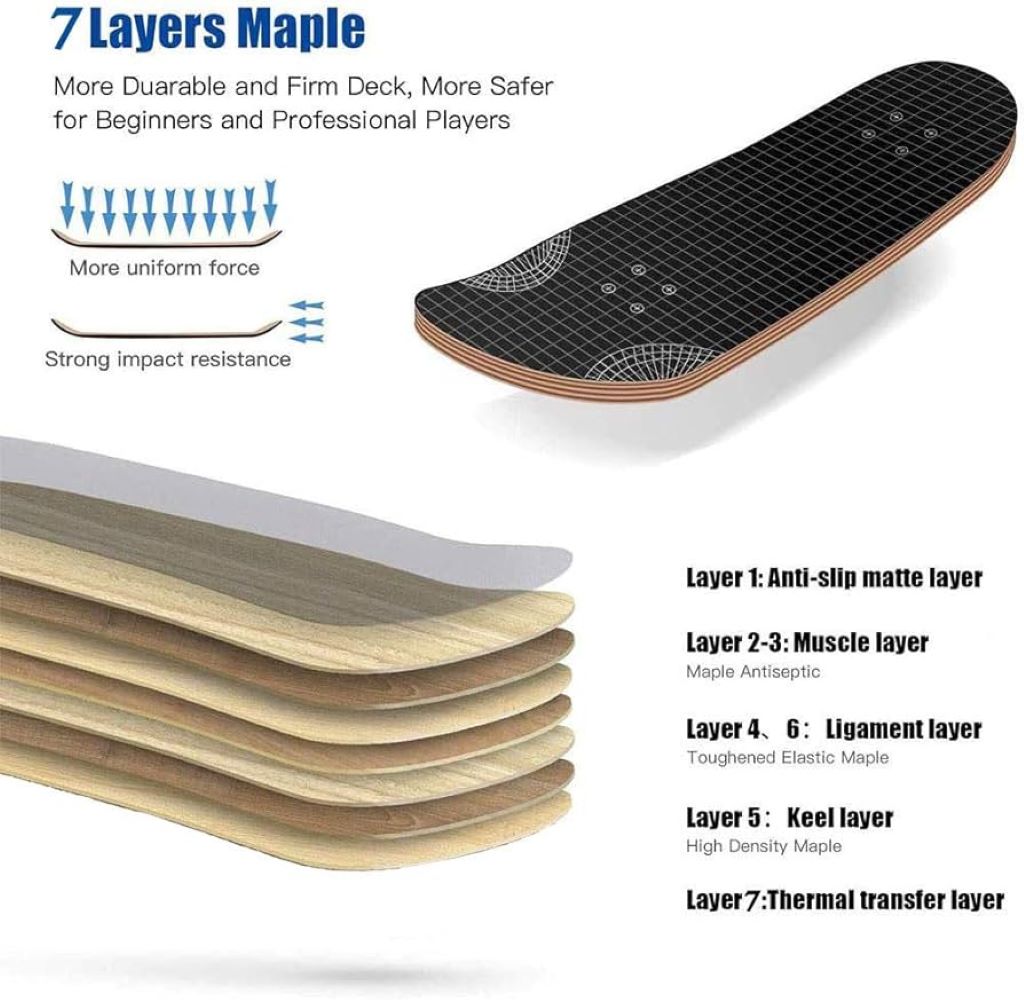

But, you might be wondering, exactly how many veneers are in a deck? Well, a typical skateboard deck consists of seven to nine layers of wood veneers. Each layer is coated with a special type of glue and then pressed together under immense pressure. This method gives the deck its distinct shape and curve, known as the “concave”, which helps control the board while riding and performing tricks.

Now, the question of how much is a good skateboard depends on various factors such as the quality of the wood, the brand, and the craftsmanship involved in making the deck. A higher-quality skateboard with excellent craftsmanship can run a bit more expensive, but the performance, durability, and overall ride experience it offers are well worth the investment. So, next time you’re in the market for a skateboard, remember that you’re not just buying a piece of wood with wheels, but a finely crafted piece of sporting equipment made from multiple layers of quality wood veneers.

The Skateboard Manufacturing Process

Skateboards are usually made in factories using industrial machinery and techniques. The process starts with cutting thin layers of wood veneers, typically maple or birch, into the desired shape and size of the deck. These veneers are then glued together with a strong adhesive, creating a sturdy and durable base for the skateboard.

The next step involves shaping the deck, which is usually done using a mold or press machine. This process gives the deck its characteristic concave shape, making it easier for riders to perform tricks and maintain control while riding.

After the deck is shaped and pressed, it goes through a finishing process where the edges are smoothed out, and any excess glue or imperfections are removed. The finish of the deck can vary depending on personal preference and style, such as adding graphics or leaving it plain wood.

Once the deck is complete, holes are drilled into it for attaching the trucks. The trucks are then mounted onto the deck using bolts and nuts, followed by attaching the wheels and bearings. Finally, grip tape is applied on top of the deck, completing the skateboard.

The Number of Wood Pieces in a Skateboard

Now that we understand how a skateboard is made let’s answer the question at hand – how many pieces of wood are used in making a skateboard? As mentioned earlier, the deck is made of multiple layers of wood veneers pressed together. The number of veneer sheets used can vary depending on the desired stiffness and strength of the deck. However, on average, a skateboard deck consists of 7 to 9 layers of wood veneers.

Therefore, a typical skateboard is made up of at least 7 pieces of wood, and sometimes more if additional layers are added for strength. This number can vary depending on the brand, style, and size of the skateboard.

FAQs

What type of wood is used in making skateboard decks?

The most common types of wood used in making skateboard decks are maple and birch due to their strength and durability.

Can skateboards be made with one solid piece of wood?

No, skateboards need multiple layers of wood veneers glued together to achieve the desired flexibility and strength.

How long does it take to make a skateboard?

The manufacturing process can vary, but on average, it takes 2-3 days for a skateboard to be made in a factory setting.

Are there any environmentally friendly options for skateboards?

Yes, there are some brands that use sustainably sourced wood and eco-friendly materials in making their skateboards.

Can I make my own skateboard at home?

It is possible to make your own skateboard at home, but it requires specialized tools and skills. It is recommended to leave the manufacturing process to professionals for safety reasons.

Conclusion

A skateboard is made up of multiple components, with the deck being the main part. Considering that the deck consists of 7 to 9 layers of wood veneers pressed together and shaped into the desired concave shape, you should definitely wear a helmet when skateboarding, as safety should always be a top priority.

Whether you are a beginner or an experienced skateboarder, it’s always interesting to know the details of how your beloved sport and hobby is made. Now that you have a better understanding of the process, go out and enjoy riding on your trusty wooden skateboard!